Cellulose triacetate

| |

| Names | |

|---|---|

| Other names

2,3,6-Tri-O-acetyl cellulose; cellulose triacetate polymer; triacetylcellulose | |

| Identifiers | |

| 9012-09-3 | |

| ECHA InfoCard | 100.115.198 |

| Properties | |

| variable | |

| Molar mass | variable |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| | |

| Infobox references | |

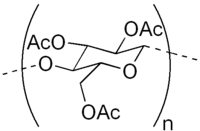

Cellulose triacetate, also known simply as triacetate, CTA and TAC, is a chemical compound manufactured from cellulose and a source of acetate esters, typically acetic anhydride. Triacetate is typically used for the creation of fibres and film base. It is similar chemically to cellulose acetate, with the distinguishing characteristics being that in triacetate, according to the Federal Trade Commission definition, at least "92 percent of the hydroxyl groups are acetylated." During the manufacture of triacetate the cellulose is completely acetylated whereas in regular cellulose acetate or cellulose diacetate, it is only partially acetylated. Triacetate is significantly more heat resistant than cellulose acetate.

History

Triacetate, whose chemical equation is [C6H7O2(OOCCH3)3]n, was first produced commercially in the U.S. in 1954 by Celanese Corporation . Mitsubishi Rayon Co., Ltd., is the only company that still produces the fiber. Eastman Kodak formerly manufactured cellulose triacetate. They discontinued this product on March 15, 2007. In 2010 Eastman Chemical announced a 70% increase in cellulose triacetate output at its Kingsport, TN manufacturing site in late 2010 to supply increasing demand for the chemical's use as an intermediate in the production of polarized films for liquid crystal displays (LCD)s.[1][2]

Production

Triacetate is derived from cellulose by acetylating cellulose with acetic acid and/or acetic anhydride. Acetylation converts hydroxyl groups in cellulose to acetyl groups, which renders the cellulose polymer much more soluble in organic solvents. The cellulose acetate is dissolved in a mixture of dichloromethane and methanol for spinning. As the filaments emerge from a spinneret, the solvent is evaporated in warm air, in a process known as dry spinning, leaving a fibre of almost pure triacetate.

A finishing process called S-Finishing or surface saponification is sometimes applied to acetate and triacetate fabrics using a sodium hydroxide solution. This removes part or all of the acetyl groups from the surface of the fibres leaving them with a cellulose coating. This reduces the tendency for the fibres to acquire a static charge.

Chemistry

CAS number 9012-09-3

As a Fibre

Triacetate fibres have a crenate cross section.

Characteristics

- Shrink resistant

- Wrinkle resistant

- Easily washable

- Generally washable at high temperatures

- Maintains creases and pleats well

Usage Scenarios

Particularly effective in clothing where crease or pleat retention is important, such as skirts and dresses.

In the 1980s triacetate was also used with polyester to create shiny tracksuits which were very popular at the time. The material was very smooth and shiny on the outside and soft and fleecy on the inside.

General Care Tips

- Ironable up to 200 °C

- Pleated garments are best hand laundered. Most other garments containing 100% triacetate can be machine washed and dried

- Articles containing triacetate fibres require very little special care due mainly to the fibre's resistance to high temperatures

As a film

Characteristics

- Resistant to grease, oil, aromatic hydrocarbons, and most common solvents

- Films have hard glossy surfaces

- Excellent optical clarity

- High dielectric constant

- Easily laminated, coated, folded, and die-cut

- Cellulose acetate film prone to degradation known as vinegar syndrome

Usage Scenarios

- Polarizer films for LCD projectors

- Specialized overhead projector transparencies

- Specialized photographic film

- Motion picture film

- Production of animation cels

- Packaging

As a semipermeable membrane

Usage Scenarios

- Water purification through reverse osmosis. The membrane may consist of a blend of cellulose acetate, diacetate and triacetate.

See also

References

- ↑ "Eastman increasing cellulose triacetate capacity". timesnews.net. Associated Press. November 3, 2010.

- ↑ Lindsey Bewley (November 1, 2010). "Eastman to Boost Cellulose Triacetate Capacity at Kingsport". IHS Chemical Week.

External links

- Description of triacetate fibre

- Description of triacetate film

- Federal Trade Commission definition of triacetate

- The long term archival of triacetate photographic films

- Glossary of terms relation to the manufacture of cellulose / acetate fibres

- Fundamentals of membranes for water treatment