Methyl acetate

| |

| |

| Names | |

|---|---|

| Preferred IUPAC name

Methyl acetate | |

| Systematic IUPAC name

Methyl ethanoate | |

| Other names

Methyl ester of acetic acid | |

| Identifiers | |

| 79-20-9 | |

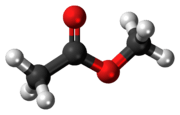

| 3D model (Jmol) | Interactive image |

| ChEBI | CHEBI:77700 |

| ChEMBL | ChEMBL14079 |

| ChemSpider | 6335 |

| ECHA InfoCard | 100.001.078 |

| KEGG | C17530 |

| PubChem | 6584 |

| UNII | W684QT396F |

| |

| |

| Properties | |

| C3H6O2 | |

| Molar mass | 74.08 g·mol−1 |

| Appearance | Colorless liquid |

| Odor | Fragrant, fruity[2] |

| Density | 0.932 g cm−3 |

| Melting point | −98 °C (−144 °F; 175 K) |

| Boiling point | 56.9 °C (134.4 °F; 330.0 K) |

| ~25% (20 °C) | |

| Vapor pressure | 173 mmHg (20°C)[2] |

| Refractive index (nD) |

1.361 |

| Hazards | |

| Safety data sheet | External MSDS |

| NFPA 704 | |

| Flash point | −10 °C; 14 °F; 263 K [2] |

| Explosive limits | 3.1%-16%[2] |

| Lethal dose or concentration (LD, LC): | |

| LD50 (median dose) |

3700 mg/kg (oral, rabbit)[3] |

| LCLo (lowest published) |

11,039 ppm (mouse, 4 hr) 21,753 ppm (cat, 1 hr) 32,000 ppm (rat, 4 hr)[3] |

| US health exposure limits (NIOSH): | |

| PEL (Permissible) |

TWA 200 ppm (610 mg/m3)[2] |

| REL (Recommended) |

TWA 200 ppm (610 mg/m3) ST 250 ppm (760 mg/m3)[2] |

| IDLH (Immediate danger) |

3100 ppm[2] |

| Related compounds | |

| Related esters |

Methyl formate Ethyl acetate |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| | |

| Infobox references | |

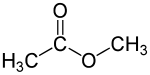

Methyl acetate, also known as MeOAc, acetic acid methyl ester or methyl ethanoate, is a carboxylate ester with the formula CH3COOCH3. It is a flammable liquid with a characteristically pleasant smell reminiscent of some glues and nail polish removers. Methyl acetate is occasionally used as a solvent, being weakly polar and lipophilic, but its close relative ethyl acetate is a more common solvent being less toxic and less soluble in water. Methyl acetate has a solubility of 25% in water at room temperature. At elevated temperature its solubility in water is much higher. Methyl acetate is not stable in the presence of strong aqueous bases or aqueous acids. Methyl acetate is not considered as a VOC.[4]

Preparation and reactions

Methyl acetate is produced industrially via the carbonylation of methanol as a byproduct of the production of acetic acid.[5] Methyl acetate also arises by esterification of acetic acid with methanol in the presence of strong acids such as sulfuric acid, this production process is famous because of Eastman Kodak's intensified process using a reactive distillation.

Reactions

In the presence of strong bases such as sodium hydroxide or strong acids such as hydrochloric acid or sulfuric acid it is hydrolyzed back into methanol and acetic acid, especially at elevated temperature. The conversion of methyl acetate back into its components, by an acid, is a first-order reaction with respect to the ester. The reaction of methyl acetate and a base, for example sodium hydroxide, is a second-order reaction with respect to both reactants.

Applications

A major use of methyl acetate is as a volatile low toxicity solvent in glues, paints, and nail polish removers.

Acetic anhydride is produced by carbonylation of methyl acetate in a process that was inspired by the Monsanto acetic acid synthesis.[6]

See also

References

- ↑ Merck Index, 12th Edition, 6089.

- 1 2 3 4 5 6 7 "NIOSH Pocket Guide to Chemical Hazards #0391". National Institute for Occupational Safety and Health (NIOSH).

- 1 2 "Methyl acetate". Immediately Dangerous to Life and Health. National Institute for Occupational Safety and Health (NIOSH).

- ↑ Zeno, W. Wicks, JR, Frank N. Jones, S. Peter Pappas, and Douglas A. Wicks (2007). Organic Coatings. Hoboken, New Jersey: Wiley. ISBN 978-0-471-69806-7.

- ↑ Hosea Cheung, Robin S. Tanke, G. Paul Torrence “Acetic Acid” in Ullmann's Encyclopedia of Industrial Chemistry, 2002, Wiley-VCH, Weinheim. doi:10.1002/14356007.a01_045

- ↑ Zoeller, J. R.; Agreda, V. H.; Cook, S. L.; Lafferty, N. L.; Polichnowski, S. W.; Pond, D. M. (1992). "Eastman Chemical Company Acetic Anhydride Process". Catalysis Today. 13: 73–91. doi:10.1016/0920-5861(92)80188-S.