Fault indicator

A fault indicator is a device which provides visual or remote indication of a fault on the electric power system. Also called a faulted circuit indicator (FCI), the device is used in electric power distribution networks as a means of automatically detecting and identifying faults to reduce outage time.

Overhead indicators are used to visualize the occurrence of an electrical fault on an overhead electrical system. Underground indicators locate faults on an underground system. Often these devices are located in an underground vault. Some fault indicators communicate back to a central location using radio or cellular signals.

Basic principles

Typically fault indicators sense magnetic field caused by current flows through a conductor or cable. Some of them also use measurement of electric field caused by voltage in conductor.

During an electrical fault on a grounded system, additional current flows through a conductor, inducing a magnetic field, which is detected up by the fault indicator causing a state change on the mechanical target flag, LED, or remote indication device. Ground fault indicators for ungrounded systems sense the vector sum of the current and look for an imbalance indicating a fault on one or more of the three phases.

Systems with earthing through high resistance have low phase-to-ground fault currents so require high sensitivity of FI. In insulated neutral systems and systems with earthing through a Petersen Coil, ground faults cannot be located with classical FI's at all. Capacitive current appears in overall faulted system so directional fault location devices are required. Some modern network protection systems e.g. GFN have time to clear a fault as small as possible down to 60ms so fault indicators must not only be highly sensitive and directional but additionally very fast.

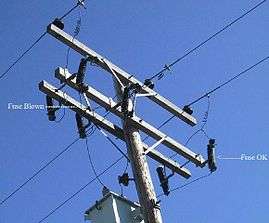

High-voltage fuses commonly drop down after operating, making it obvious where the fault is.

History

The first fault indicators came onto the market from Horstmann (Germany) in 1946. The E.O. Schweitzer Manufacturing Company (now a division of Schweitzer Engineering Laboratories, Inc.) introduced a product to the U.S.A in 1948. The first fault indicators were manual reset devices. Later fault indicators automatically reset on system restoration or after a set period of time. More recent fault indicators communicate their status (tripped or reset) via cell signal or radio to a central station, handheld device, or pole-mounted receiver.

Recent developments include a remotely programmable overhead line indicator, fault indication for paper-insulated lead cable, and an overhead fault indicator for mesh networks.

See also

- Power transmission

- Polyphase system

- Electricity distribution

- Overhead powerline

- Power outage

- Three-phase electric power