Carbonization

Carbonization (or carbonisation) is the term for the conversion of an organic substance into carbon or a carbon-containing residue through pyrolysis or destructive distillation. It is often used in organic chemistry with reference to the generation of coal gas and coal tar from raw coal. Fossil fuels generally are the products of the carbonization of vegetable matter. The term carbonization is also applied to the pyrolysis of coal to produce coke. Carbonization is also a stage in the charcoal making process, and is considered the most important step of all since it has such power to influence the whole process from the growing tree to the final distribution of charcoal to various sources.[1]

In the wool processing industry, carbonising[2] is the name for a chemical process by which vegetable matter is removed from wool, it is part of the wool scouring process.

Complexity in carbonization

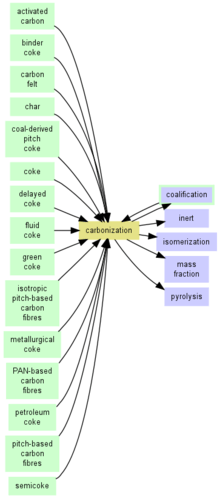

Since carbonization is a pyrolytic reaction, it is considered a complex process in which many reactions take place concurrently such as dehydrogenation, condensation, hydrogen transfer and isomerization.

Carbonization differs from coalification in that it occurs much faster, due to its reaction rate being faster by many orders of magnitude.

For the final pyrolysis temperature, the amount of heat applied controls the degree of carbonization and the residual content of foreign elements. For example, at T ∼ 1200 K the carbon content of the residue exceeds a mass fraction of 90 wt.%, whereas at T ∼ 1600 K more than 99 wt.% carbon is found.[3] Carbonization is often exothermic, which means that it could in principle be made self-sustaining and be used as a source of energy that does not produce carbon dioxide. (See.[4]) In the case of glucose, the reaction releases about 237 calories per gram.

When biomaterial is exposed to sudden searing heat (as in the case of an atomic bomb explosion or pyroclastic flow from a volcano, for instance), it can be carbonized extremely quickly, turning it into solid carbon. In the destruction of Herculaneum by a volcano, many organic objects such as furniture were carbonized by the intense heat.

How wood is transformed into charcoal

The carbonization of wood in an industrial setting usually requires a temperature above 280°C, which liberates energy and hence this reaction is said to be exothermic. This carbonization, which can also be seen as a spontaneous breakdown of the wood, continues until only the carbonised residue called charcoal remains. Unless further external heat is provided, the process stops and the temperature reaches a maximum of about 400°C. This charcoal, however, will still contain appreciable amounts of tarry residue, together with the ash of the original wood.[5]

Industrial safety in carbonization

Carbonisation produces substances which can prove harmful and simple precautions should be taken to reduce risks.

The gas produced by carbonization has a high content of carbon monoxide which is poisonous when breathed. Therefore, when working around the kiln or pit during operation and when the kiln is opened for unloading, care must be taken that proper ventilation is provided to allow the carbon monoxide, which is also produced during unloading through spontaneous ignition of the hot fuel, to be dispersed.

The tars and smoke produced from carbonization, although not directly poisonous, may have long-term damaging effects on the respiratory system. Housing areas should, where possible, be located so that prevailing winds carry smoke from charcoal operations away from them and batteries of kilns should not be located in close proximity to housing areas.

Wood tars and pyroligneous acid can be irritant to skin and care should be taken to avoid prolonged skin contact by providing protective clothing and adopting working procedures which minimize exposure.

The tars and pyroligneous liquors can also seriously contaminate streams and affect drinking water supplies for humans and animals. Fish may also be adversely affected. Liquid effluents and waste water from medium and large scale charcoal operations should be trapped in large settling ponds and allowed to evaporate so that this water does not pass into the local drainage system and contaminate streams. Fortunately kilns and pits, as distinct from retorts and other sophisticated systems, do not normally produce liquid effluent - the by-products are mostly dispersed into the air as vapours. Precautions against airborne contamination of the environment are of greater importance in this case.[6]

Carbonization and biodiesel fuels

In one study,[7] carbonization was used to create a new catalyst for the generation of biodiesel from ethanol and fatty acids. The catalyst was created by carbonization of simple sugars such as glucose and sucrose. The sugars were processed for 15 hours at 400 °C under a nitrogen flow to a black carbon residue consisting of a complex mixture of polycyclic aromatic carbon sheets. This material was then treated with sulfuric acid, which functionalized the sheets with sulfonite, carboxyl, and hydroxyl catalytic sites.

References

- ↑ Emrich, Walter. "Charcoal and Carbonization".

- ↑ Zhao, Wu (1987). "A study of wool carbonizing". Retrieved 12 August 2014.

- 1 2 Nic, M. "Carbonization". IUPAC Gold Book.

- ↑ "Burying biomass to fight climate change" by Richard Lovett, New Scientist, 3 May 2008, pp. 32-5.

- ↑ Emrich, Walter. "Transformation of Wood into Charcoal".

- ↑ "Simple Technologies in Charcoal Making". Food and Agriculture Organization of the United Nations.

- ↑ Green chemistry: Biodiesel made with sugar catalyst Masakazu Toda, Atsushi Takagaki, Mai Okamura, Junko N. Kondo, Shigenobu Hayashi, Kazunari Domen and Michikazu Hara Nature 438, 178 (10 November 2005) doi:10.1038/438178a Abstract

External links

| Look up carbonization in Wiktionary, the free dictionary. |