Aggregated diamond nanorod

Aggregated diamond nanorods, or ADNRs, are a nanocrystalline form of diamond, also known as nanodiamond or hyperdiamond.

Discovery

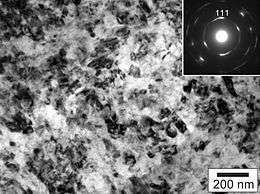

Nanodiamond was convincingly demonstrated to be produced by compression of graphite in 2003 and in the same work found to be much harder than bulk diamond.[2] Later it was also produced by compression of fullerene and confirmed to be the hardest and least compressible known material, with an isothermal bulk modulus of 491 gigapascals (GPa), while a conventional diamond has a modulus of 442–446 GPa; these results were inferred from X-ray diffraction data, which also indicated that ADNRs are 0.3% denser than regular diamond.[3] The same group later described ADNRs as "having a hardness and Young's modulus comparable to that of natural diamond, but with 'superior wear resistance'".[4]

Hardness

A <111> surface (normal to the largest diagonal of a cube) of pure diamond has a hardness value of 167±6 GPa when scratched with a nanodiamond tip, while the nanodiamond sample itself has a value of 310 GPa when tested with a nanodiamond tip.[5] However, the test only works properly with a tip made of harder material than the sample being tested. This means that the true value for nanodiamond is likely somewhat lower than 310 GPa.

Synthesis

ADNRs are produced by compressing fullerite powder — a solid form of allotropic carbon fullerene — with two somewhat similar methods. One uses a diamond anvil cell and applied pressure ~37 GPa without heating the cell.[6] In another method, fullerite is compressed to lower pressures (2–20 GPa) and then heated to a temperature in the range of 300 to 2,500 K (27 to 2,227 °C).[7][8][9][10] Extreme hardness of what now appears likely to have been nanodiamonds was reported by researchers in the 1990s.[5][6] The material is a series of interconnected diamond nanorods, with diameters of between 5 and 20 nanometres and lengths of around 1 micrometre each.

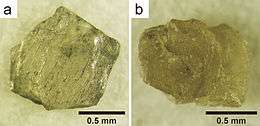

Nanodiamond aggregates ca. 1 mm in size also form in nature, from graphite upon meteoritic impact, such as that of the Popigai crater in Siberia, Russia.[11]

See also

- Adamant

- Carbon nanotube

- Diamond

- Fullerite

- Lonsdaleite

- Mohs scale of mineral hardness

- Rhenium diboride

References

- 1 2 3 Ohfuji, Hiroaki; Irifune, Tetsuo; Litasov, Konstantin D.; Yamashita, Tomoharu; Isobe, Futoshi; Afanasiev, Valentin P.; Pokhilenko, Nikolai P. (2015). "Natural occurrence of pure nano-polycrystalline diamond from impact crater". Scientific Reports. 5: 14702. Bibcode:2015NatSR...514702O. doi:10.1038/srep14702. PMC 4589680

. PMID 26424384.

. PMID 26424384. - ↑ Irifune, Tetsuo; Kurio, Ayako; Sakamoto, Shizue; Inoue, Toru; Sumiya, Hitoshi (2003). "Materials: Ultrahard polycrystalline diamond from graphite". Nature. 421 (6923): 599–600. Bibcode:2003Natur.421..599I. doi:10.1038/421599b. PMID 12571587.

- ↑ Dubrovinskaia, Natalia; Dubrovinsky, Leonid; Crichton, Wilson; Langenhorst, Falko; Richter, Asta (2005). "Aggregated diamond nanorods, the densest and least compressible form of carbon". Applied Physics Letters. 87 (8): 083106. Bibcode:2005ApPhL..87h3106D. doi:10.1063/1.2034101.

- ↑ Dubrovinskaia, Natalia; Dub, Sergey; Dubrovinsky, Leonid (2006). "Superior Wear Resistance of Aggregated Diamond Nanorods". Nano Letters. 6 (4): 824. Bibcode:2006NanoL...6..824D. doi:10.1021/nl0602084. PMID 16608291.

- 1 2 Blank, V (1998). "Ultrahard and superhard phases of fullerite C60: Comparison with diamond on hardness and wear" (PDF). Diamond and Related Materials. 7 (2–5): 427. Bibcode:1998DRM.....7..427B. doi:10.1016/S0925-9635(97)00232-X. Archived from the original (PDF) on 2011-07-21.

- 1 2 Blank, V; Popov, M; Buga, S; Davydov, V; Denisov, V; Ivlev, A; Marvin, B; Agafonov, V; et al. (1994). "Is C60 fullerite harder than diamond?". Physics Letters A. 188 (3): 281. Bibcode:1994PhLA..188..281B. doi:10.1016/0375-9601(94)90451-0.

- ↑ Kozlov, M (1995). "Superhard form of carbon obtained from C60 at moderate pressure". Synthetic Metals. 70: 1411. doi:10.1016/0379-6779(94)02900-J.

- ↑ Blank, V (1995). "Ultrahard and superhard carbon phases produced from C60 by heating at high pressure: structural and Raman studies". Physics Letters A. 205 (2–3): 208. Bibcode:1995PhLA..205..208B. doi:10.1016/0375-9601(95)00564-J.

- ↑ Szwarc, H; Davydov, V; Plotianskaya, S; Kashevarova, L; Agafonov, V; Ceolin, R (1996). "Chemical modifications of C under the influence of pressure and temperature: from cubic C to diamond". Synthetic Metals. 77: 265. doi:10.1016/0379-6779(96)80100-7.

- ↑ Blank, V (1996). "Phase transformations in solid C60 at high-pressure-high-temperature treatment and the structure of 3D polymerized fullerites". Physics Letters A. 220: 149. Bibcode:1996PhLA..220..149B. doi:10.1016/0375-9601(96)00483-5.

- ↑ Ohfuji, Hiroaki; Irifune, Tetsuo; Litasov, Konstantin D.; Yamashita, Tomoharu; Isobe, Futoshi; Afanasiev, Valentin P.; Pokhilenko, Nikolai P. (2015). "Natural occurrence of pure nano-polycrystalline diamond from impact crater". Scientific Reports. 5: 14702. Bibcode:2015NatSR...514702O. doi:10.1038/srep14702. PMC 4589680

. PMID 26424384.

. PMID 26424384.

External links

| Wikimedia Commons has media related to Nanodiamonds. |

- The invention of aggregated diamond nanorods at Physorg.com

- Michelle Jeandron (August 26, 2005). "Diamonds are not forever". Physics World.